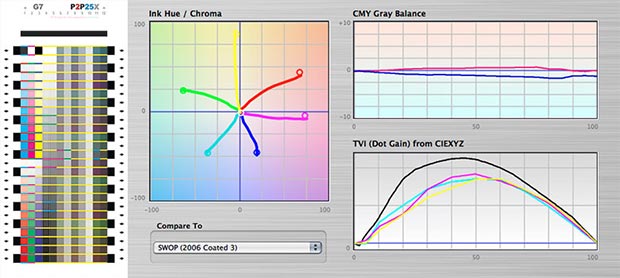

G7 is a proof-to-print process developed by the IDEAlliance that uses spectrophotometry to calibrate presses by the numbers to specifications like SWOP, GRACoL or FOGRA. Previous press calibration methods relied upon basic densitometry, dot gain and visual analysis and could take days of press runs and tweaking to get done fairly well. Because of the ambiguity and expense of these older methods most print shops don’t even bother. It is extremely common in this day and age for print shops to claim they “print to SWOP” when they haven’t taken any steps to calibrate to SWOP. Platesetter calibration is often confused with SWOP calibration. Ask a print shop to show your their SWOP (or GRACoL or FOGRA) calibration test results and most of them won’t know what you are talking about. Print shops have had to put up with a variety of customer complaints and salesmen constantly showing up with all kinds of solutions to their problems. While I can’t blame them for their thick skin, I believe G7 is their real solution. Without calibration every press prints differently which leads to poor proofing, long press checks and less than optimal final results.

IDEALinkCurve is new a software application that simplifies G7 press calibration without the tedium and uncertainty of manual curve editing. Not only does it provide the RIP curves necessary for accurate printing but it provides a wealth of new ways to analyze color, hue, TVI and gray balance. The G7 method combined with IDEALinkCurve allows someone like myself to calibrate a press extremely accurately in hours instead of days.

I have been calibrating presses this way since early 2007 am really excited about it. We have had spectrophotometry-based methods of calibrating inkjet and photo paper printers for years so it’s great to finally see the offset industry get up to speed with well adapted techniques for calibrating “the devil’s color mode” (CMYK).

I think it is time for a big call to arms for everyone in the printing industry (art directors, designers, print brokers, prepress professionals and print shop owners) to educate themselves about G7 method press calibration. Art directors, designers, and print brokers should start asking their print vendors if their presses are calibrated, and if so, with what method. Print shop owners and prepress professionals that embrace G7 calibration with an open mind might find that it’s what they’ve been looking for throughout their career. Print shops can empower their sales staff with their own SWOP calibration results and samples to show to existing and prospective customers.

Well calibrated presses translate into lower operating costs, faster press ready times, reduced or eliminated press checking, better press to press matching, better proof to print matching, reduced makeovers and most importantly, optimal quality. It is in all of our best interests to calibrate our presses, work with those who do and encourage those who are not yet doing so.

Download the Calibrating, Printing and Proofing by the G7 Method PDF for some excellent reading on this process. We also have a collection of related offset printing links on the Links page.

[this article originally appeared in Newsletter #20 June 2007]