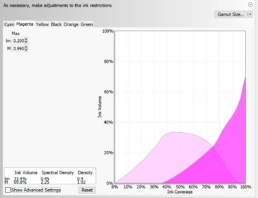

The first step to calibrating a printer in a RIP is to set the per channel ink restrictions. The challenge here is that RIPs typically have very poor (or no) tools for determining the optimal settings. The first screen grab below shows a popular RIP that encourages you to set the ink sliders without any guidance whatsoever. Color consultants are pretty good at making educated guesses, or at least have a crude process for getting close. The second screen grab below shows another popular RIP’s Ink Restrictions process where it determines the values automatically, but these settings are typically conservative and starve users of the full color gamut the process is capable of.

ChromaMax addresses this with a simple procedure. Simply print the ChromaMax Ink Restrictions target, measure and graph the results to determine the optimal Ink Restriction values for each channel. This eliminates the sloppy guesswork and enables precision.

Email us if you’d like to talk more about ink restrictions or ChromaMax calibration at your location.

Great to see that you have taken time implement your own approach as I totally agree that the Linearization systems built into many rips are less than optimal!

It’s crazy that RIPs don’t offer better guidance for this isn’t it? There really is a precise point at which more ink is only wasteful and can actually hurt saturation. I’ve been using this approach in every RIP for over 20 years now and it serves me really well.